The galvanized pipe technical parameters as following:

Standard: ASTM A53 ,BS1387,GB/T3091

Main Steel Tube Grade : A,B. Q195,Q215,Q235,Q345

Ends: PLAIN ENDS/ THREADING ENDS/BEVELLED

Zinc coating:200-300G/M2 For BS STANDARD, 500-550G/M2 for ASTM Standard,

according to customer requirement

Package: BUNDLES/ PVC COVER BUNDLE

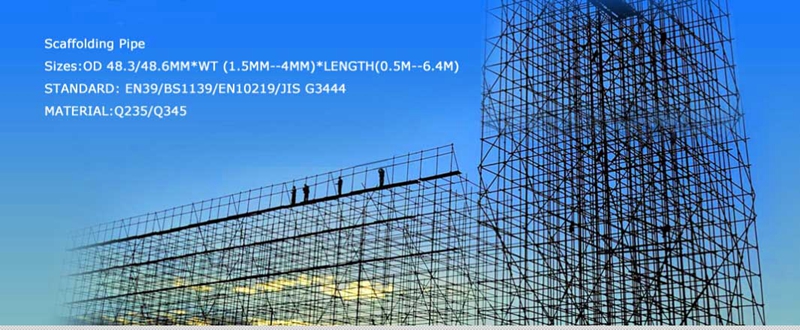

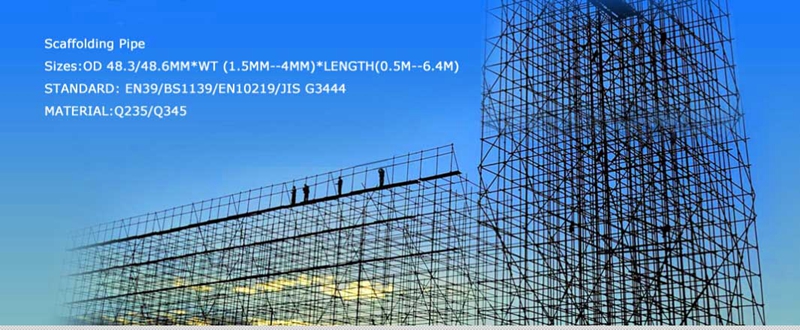

SCAFFOLDING PIPE(BLACK /HOT DIP GALVANIZED)

scaffolding pipe

scaffolding pipe hot dipped galvanized scaffolding pipe

hot dipped galvanized scaffolding pipe

1.PIPES STANDARD: EN39/BS 1139/EN10219/JIS G3444

2. MATERIAL of the scaffolding pipe:Q235/Q345/STK400/STK500

3. POPULAR SIZES :48.3MM/48.6MM*1.5MM—4MM*

the length scale 1M/1.5M/2M/2.5M/3M/4M/5M/6M/6.4M

Zinc coating 200G/M2-300G/M2

Pre-galvanized scaffolding pipe 48.6MM*2.2MM*6M/5.8M

4. ENDS: PLAIN ENDS

5. SURFACE: EMBOSSING(STAMPING)/PAINTING

|

Technical Specification of the scaffolding pipe |

|

Size |

Thickness |

Ovality |

Weight |

|

inches |

mm |

inches |

mm |

inches |

mm |

lbs/foot |

kg/m |

|

1 ½ |

48.3 |

0.126 |

3.2 |

0.02 |

0.5 |

2.392 |

3.56 |

|

1 ½ |

48.3 |

0.157 |

4.0 |

0.02 |

0.5 |

2.937 |

4.37 |

|

![]() |

|

Tolerances |

|

Outside Diameter |

Thickness |

Weight |

|

± 0.5 mm |

+/- 10% |

+/- 7.5% on Single Tube |

|

Steel Grade |

S235GT(Q235B) |

|

Mechanical Properties |

|

|

Yield Strength |

235 MPA Min. |

|

Tensile Strength |

340/ 520 MPA |

|

Elongation |

24% Min. |

|

Chemicals Composition |

|

|

Carbon |

0.20% Max. |

|

Silicon |

0.05% Max. |

|

Manganese |

0.40% Max. |

|

Phosphorous |

0.040% Max. |

|

Sulphur |

0.045% Max. |

|

Aluminium |

0.02% Min. |

|

End Finish |

Square Cut |

|

Straightness |

1 mm in 500 mm |

|

Flattening Test |

Two Stages |

|

|

Flatten upto 75% of Tube Dia for Weld |

|

|

Flatten upto 60% of Tube Dia for Material |

|

Zinc Coating |

40 Microns Minimum Outside |

|

Delivery Condition |

a) As Rolled Condition (Without Protection) |

|

|

b) Hot Dip Galvanized |

|

Any more details please contact us!

Leave us a message, please!